Current Projects

See What We Are Working On Now!

Delorio's Foods Inc. - Utica, NY

Custom Blast Freezer for De'Lorio's frozen food UTICA, NY.

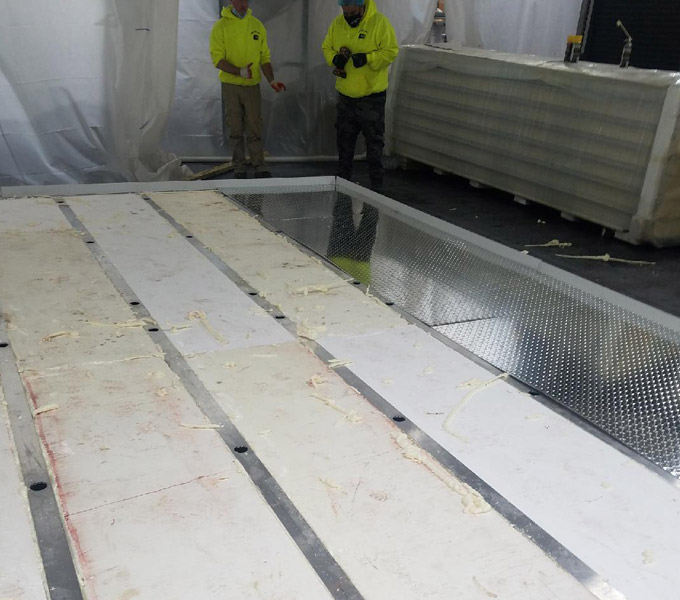

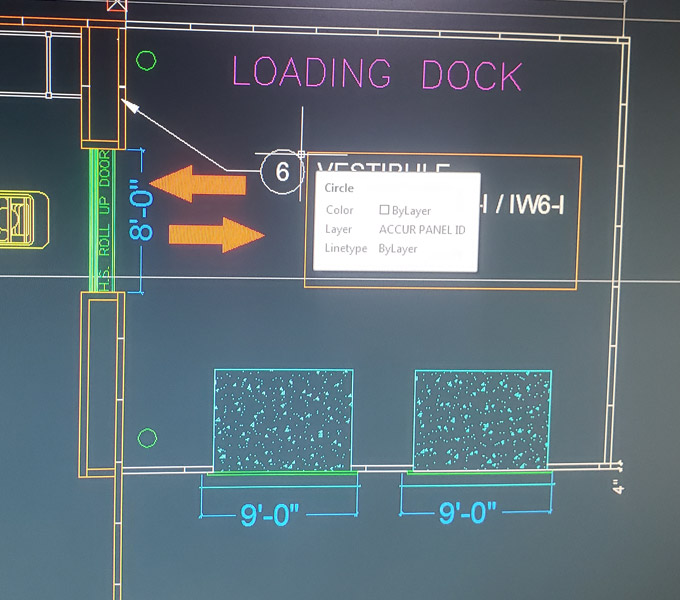

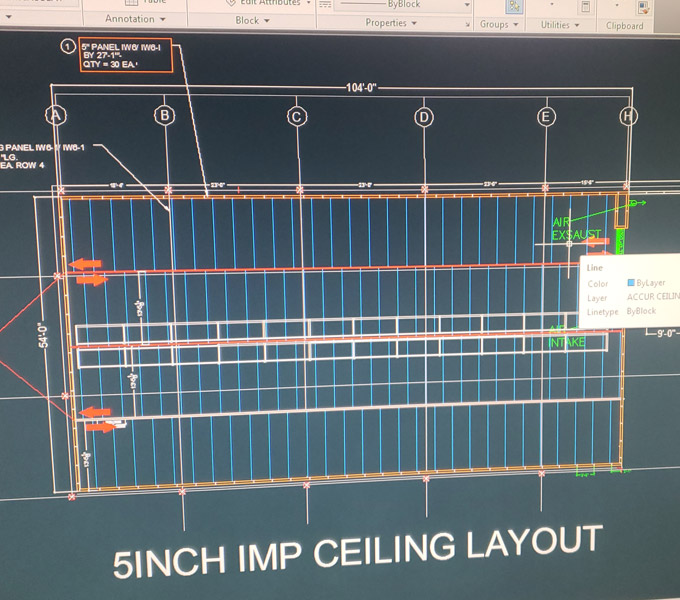

Accurate Refrigeration Design had to design a insulated blast freezer floor because we could not dig up the concreate for the blast freezer floor in the production area because they could not shut down for construction. So we designed a 3" thick raise 1/4" thick diamond plate floor all made custom out tubed aluminum studs with 3" square tubing and sued 40PSI insulation in-between the tubes shown in blue prints.

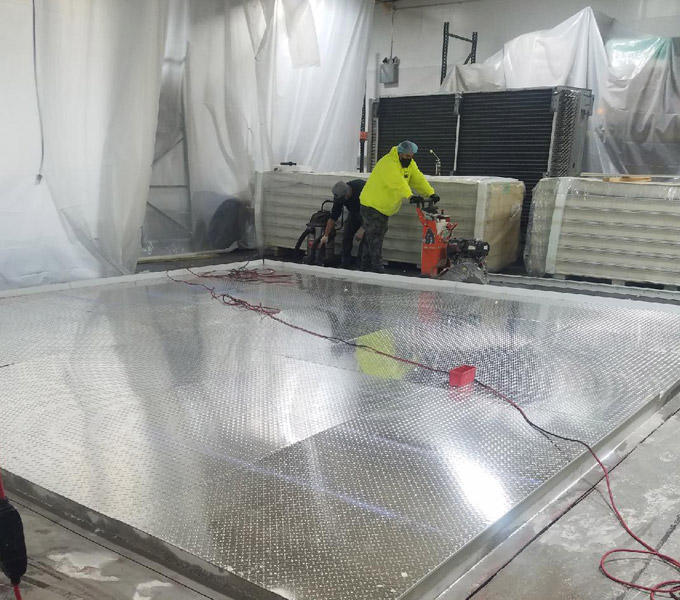

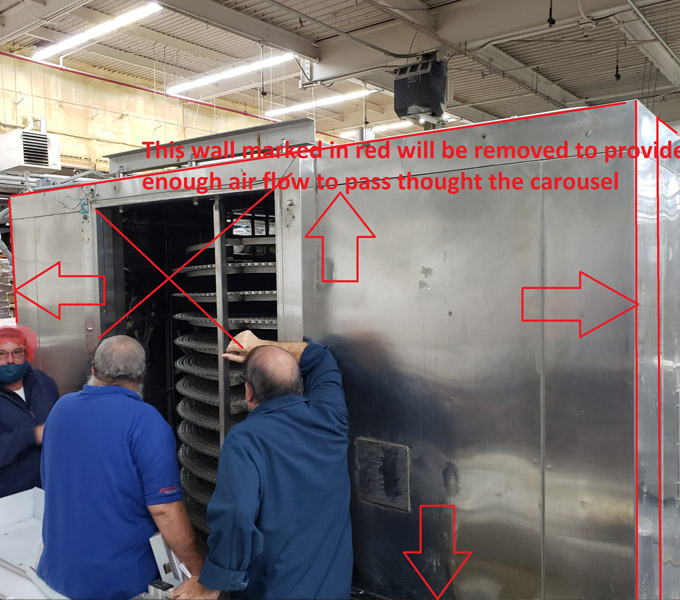

We then cover the entire floor in the 1/4" thick diamond plate we removed the 2 side walls off the old existing spiral Stainless steal Industrial blast freezer box .size 116" x 108" x 110". We then designed and built a brand new blast freezer to surround the old blast freezer box with 6inch thick 20' x 20' x 15' and then installed the old blast freezer in the new enclosure.

We also added a couple of Freezer Man Doors 36" x 84" and evaporator /coil and now there up and running with out a stop introduction all labor/ demo work was provided Cooler panel Pros and the installation of all mechanical MEP work was done by Mullally Bro's out of Troy, NY

Deli Boy - Syracuse, NY

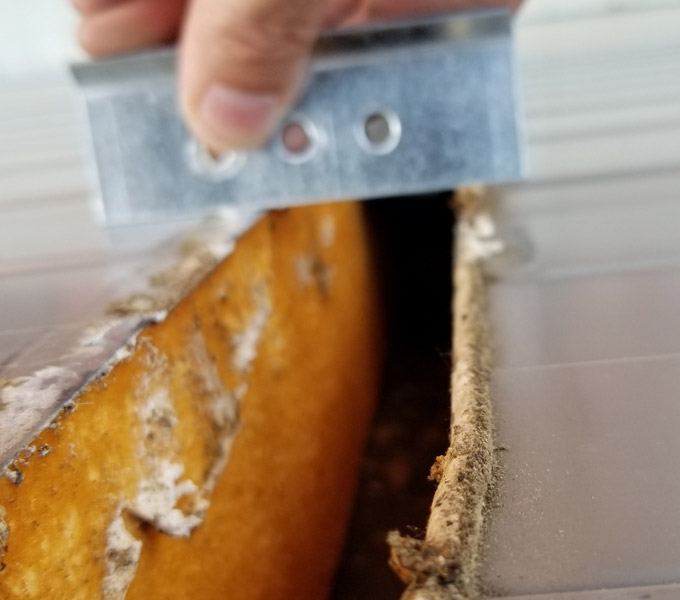

Accurate Refrigeration Design, Mike Lapreski, Deli Boy, and ABR Masonry, were all called in to repair a existing freezer that was failing to keep temperature and having to raise the concrete from ice building up under the sub slab of concrete.

Once ABR concrete removed the 230 yards of concrete, they installed 230 yard of crushed stone. Accurate had to replace the entire freezer.

Accurate designed and installed the new PVC forced air system and 6" of insulation. They also installed a 5" thick new freezer 105' × 55' x 28', inside the old freezer.

XAL - Oxford, Connecticut

Accurate Refrigeration Design, AWIP, and Starcity-IPS removed

and reinstalled 10,000 Square foot of Horizontal IMP 30 feet long

3" panels. This project was under a tight time frame, as we only had 10

days to complete this project from start to finish. StarCity-IPS did it in 8 days. We used a mini-clad panel lifter from the GGR Group to compete this project early.

Blue Ridge Beverage - Virginia

Blue Ridge Beverage is Virginia's largest full-service beverage distributor.

ARD worked with StarCity* IPS, for this special custom installation.

StarCity IPS Installed 29'-3" 6 inch fire rated panels from metlspan using a clad-Boy lifter. With clams and straps to keep the panels from bending or folding. This is for the high skilled professional to install this Very heavy wool core panels each panel weighed 745 lbs. and there was 6,700 sq ft of this type of fire rated panel.

Some Completed Projects

Tommy Oliver Stadium

view project

Cipriani Club 55

view project

Ultra Dairy

view project

Rutgers University Food

view project

Dennis Paper & Food Services

view project

DeCrescente Distribution

view project

DeCrescente Truck Wash

view project

Hill Farmstead Brewery

view project

Chobani Yogurt

view project

Franklin County CDC

view project

Delight Foods

view project

Milmar Food Group

view project

VT Commonwealth Dairy

view project

Dannon Yogurt

view project

Bagel Boy

view project

RockTenn

view project

Bakery on Main

view project

Ascent Pharmaceuticals

view project

Dolce Amore

view project

Hilary's

view project

Anheuser Busch

view project

Ferraro Foods

view project

Orwashers Bakery

view project

Satin Fine Foods

view project

Lincoln's Challenge Academy

view project

Vermont Smoke and Cure

view project

121 Inflight Catering

view project

Byrne Dairy

view project

Orange & Rockland

view project

Capital Candy

view project

VT Commonwealth Dairy

view project

Food Bank for Westchester

view project